Prime contractor Goldbeck Ost subcontracted the complex structural works of the Production plant in Waltershausen to the Strobel company from Coburg, which deployed three different formwork types, all of which use the same fittings.

Combination of steel and aluminium units

Despite a total height of almost 12 m, there are only two storeys, 5.31 m and 5.95 m high, the floors of which are supported by 1 m deep beams, which are in turn carried by square columns on an irregular grid. Strobel has long since been using formwork from Mayer Schaltechnik for almost all its concreting works, and has many Mayer products among its own stocks. Those include the aluminium panels of the ultraMAX L multi-purpose formwork, the heavy-duty ultraMAX S steel panels and the lightweight aluMAX hand-set formwork. The special feature of all these formwork systems is that they all use the same accessories, connectors and ties, making all three systems compatible with each other

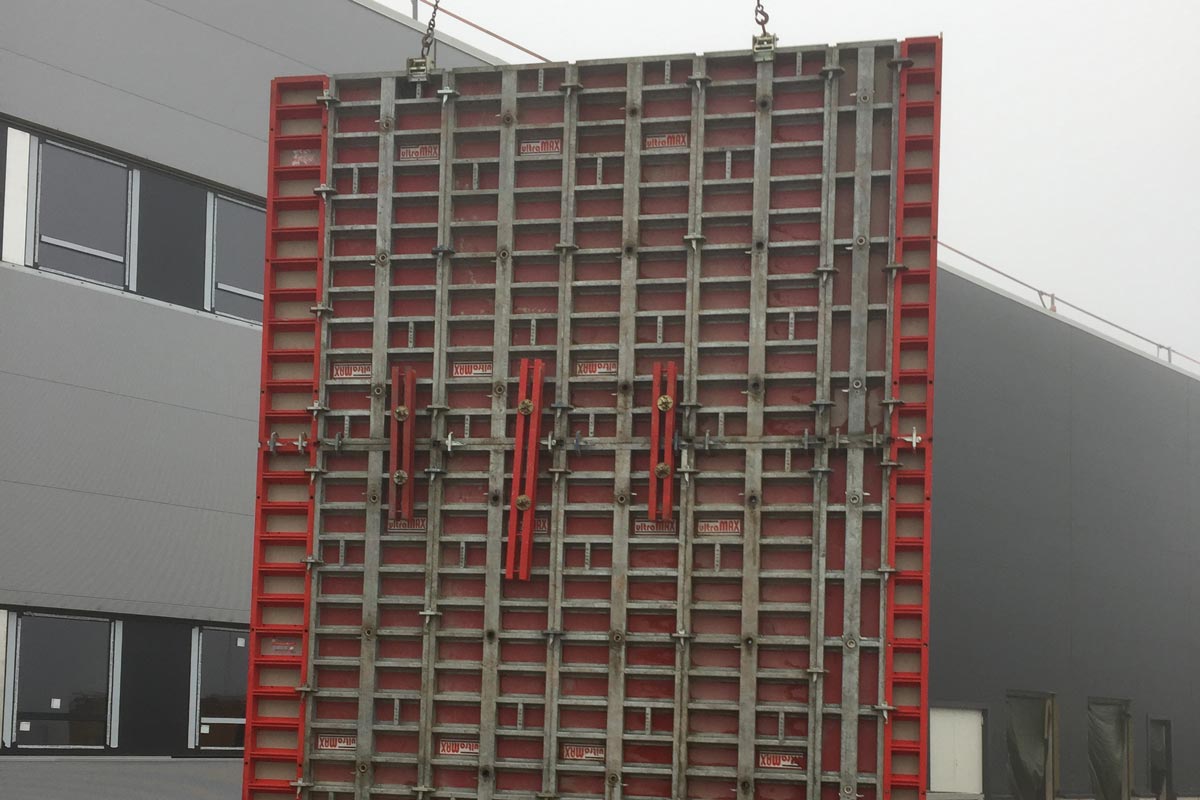

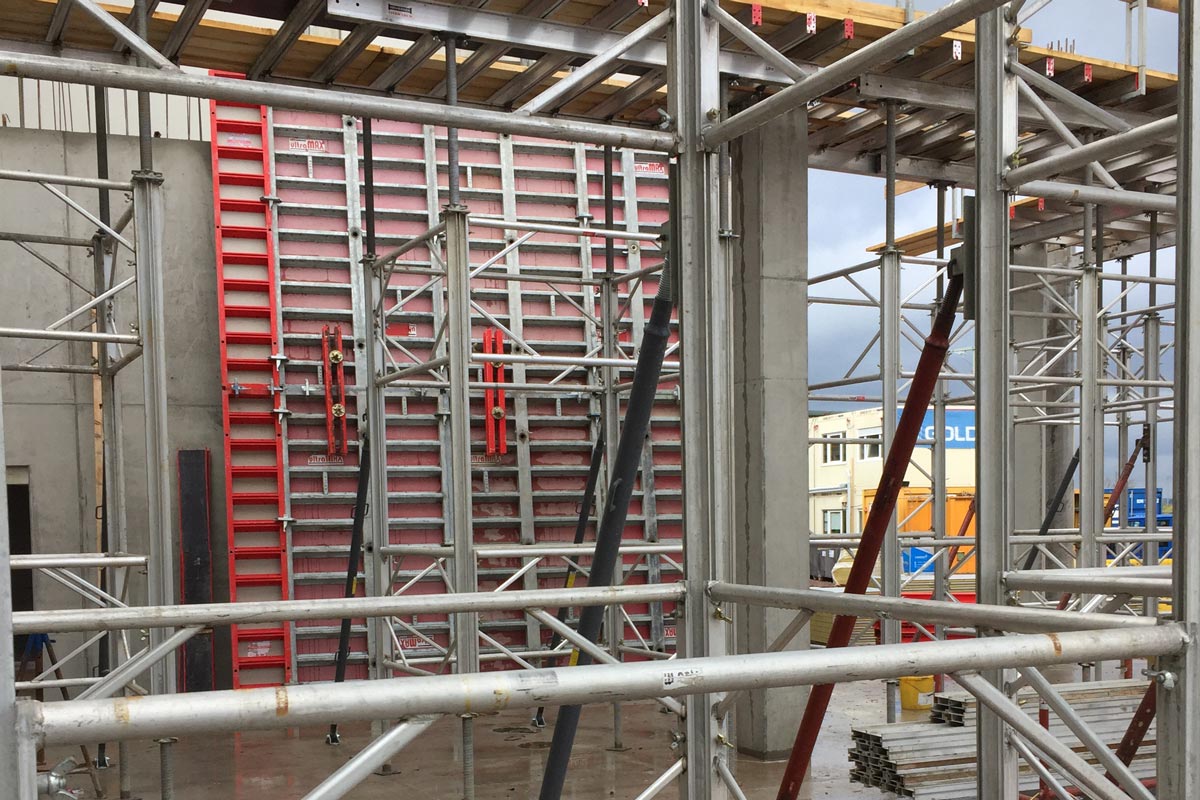

The almost 500 m² of 25 cm thick walls in Waltershausen were built chiefly with ultraMAX S and ultraMAX L wall formwork components from the contractor’s own stocks. Large quantities of Ischebeck TITAN HV floor slab formwork and TITAN aluminium falsework were also required; MST is the regional representative for Ischebeck. Strobel used the heavy-duty large-format ultraMAX S formwork for the 5–6 m high walls on the ground and first floors which separate the offices from the production bays. For these walls, the hot-dip galvanised steel frames were extended to form larger units that have to be moved by crane. Contrasting with this, the lightweight ultraMAX L aluminium formwork was preferred for the 1 m deep downstand beams and the parapets. These units are easily handled by two people, as the 300 x 100 cm standard panel weighs only 71 kg. That saves waiting for the crane.

Strobel used the PAX HD folding column formwork for the many square and rectangular columns. PAX HD was the first product from MST and marked the transformation from formwork distributor to formwork manufacturer more than 20 years ago. This clever system – in the meantime copied many times but to a lower standard – allows square and rectangular columns with different cross-section dimensions to be built extremely accurately and economically. PAX HD is not only set up and aligned quickly, but also ensures excellent concrete surfaces.

We look forward to hearing from you!

Richtbergstraße 8

97493 Bergrheinfeld

Germany

info@mayerschaltechnik.de

Phone: +49 (0)9721-78960

Fax: +49 (0)9721-789666

Wir freuen uns über Ihre Kontaktaufnahme!

We looking forward to hearing from you!

We look forward to hearing from you!

We look forward to hearing from you!