Once Ulsenheimer Bau had secured the contract for the new water reservoir, it was obvious to director Ernst Muser jnr. that an experienced partner was needed to help with the complexities of this project. “When it comes to such demanding building measures in fair-face quality, we only work together with Mayer Schaltechnik,” says Ernst Muser jnr., “because mutual trust defines our business relationship. We can rely fully on the excellent formwork products and dependable support of Mayer Schaltechnik.”

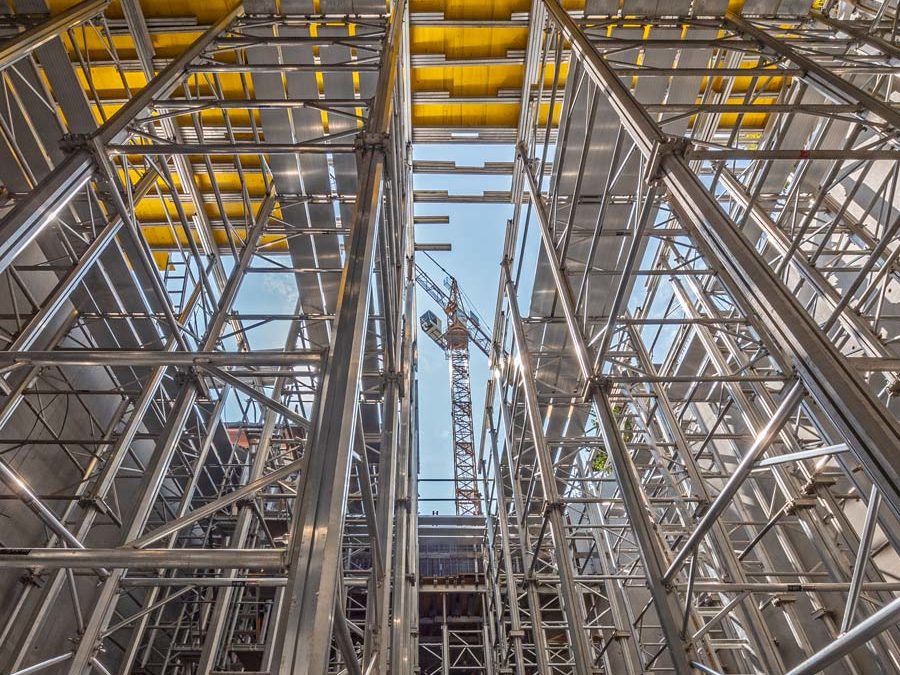

PRIMAX steel beam formwork has proved its worth in challenging projects and therefore Mayer Schaltechnik supplied PRIMAX for this structure, too. The 45 cm thick x max. 10.57 m high external wall to the water reservoir was concreted in eight concrete pours.

PRIMAX is well known for fair-face concrete tasks because of its excellent stiffness and dimensional accuracy and the ensuing exceptionally flat concrete surfaces, but also because of the variable height adjustment. The galvanised steel beams and their telescoping parts enable formwork to be set up for different wall heights. On this project the wall was almost 11 m high. Even at this height, PRIMAX still remains stable under the full weight of the wet concrete and vibratory compaction – even when running external vibrators at full power. And such vibrators were used in Erlangen as the height of the wall and the very heavy reinforcement ruled out the use of poker vibrators for Ernst Muser jnr. Optimum surfaces are essential in drinking water structures. Therefore, cement slurry leaks at joints must be avoided at all costs. Zemdrain formwork liner was attached to the sheeting on the water side to create a lightly textured surface virtually free from pores. It works by draining the excess water from the concrete near the surface, which leaves the surface harder, denser and more resistant. Furthermore, release agents are then totally unnecessary – a highly desirable bonus for drinking water reservoirs.

In total, the Ulli-Bau team built 985 m² of wall surfaces. On this project, apart from the 380 m² of curved PRIMAX formwork, another 183 m² of straight PRIMAX panels were used for the central dividing wall. In addition, 67 m² of ultraMAX L lightweight aluminium wall formwork were required for the cramped areas between existing wall and new reservoir plus a few aluMAX hand-set formwork components for the reservoir’s high-level outlet wall. Site supervisor Karl Hörner sums up the job: “Without the technical support of Mayer Schaltechnik – essentially, without the telescopic PRIMAX formwork – for this complex water reservoir with its almost 11 m high walls, we might have been faced with a disaster…”

We look forward to hearing from you!

Richtbergstraße 8

97493 Bergrheinfeld

Germany

info@mayerschaltechnik.de

Phone: +49 (0)9721-78960

Fax: +49 (0)9721-789666

Wir freuen uns über Ihre Kontaktaufnahme!

We looking forward to hearing from you!

We look forward to hearing from you!

We look forward to hearing from you!