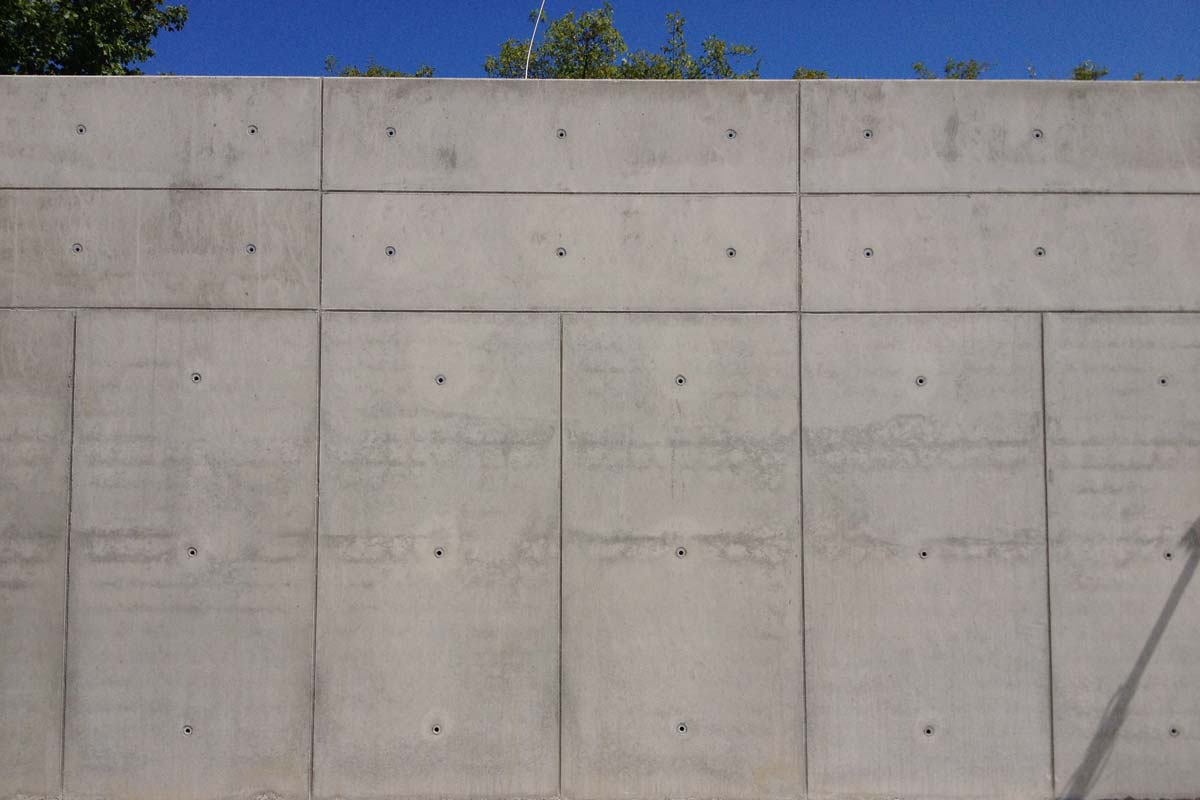

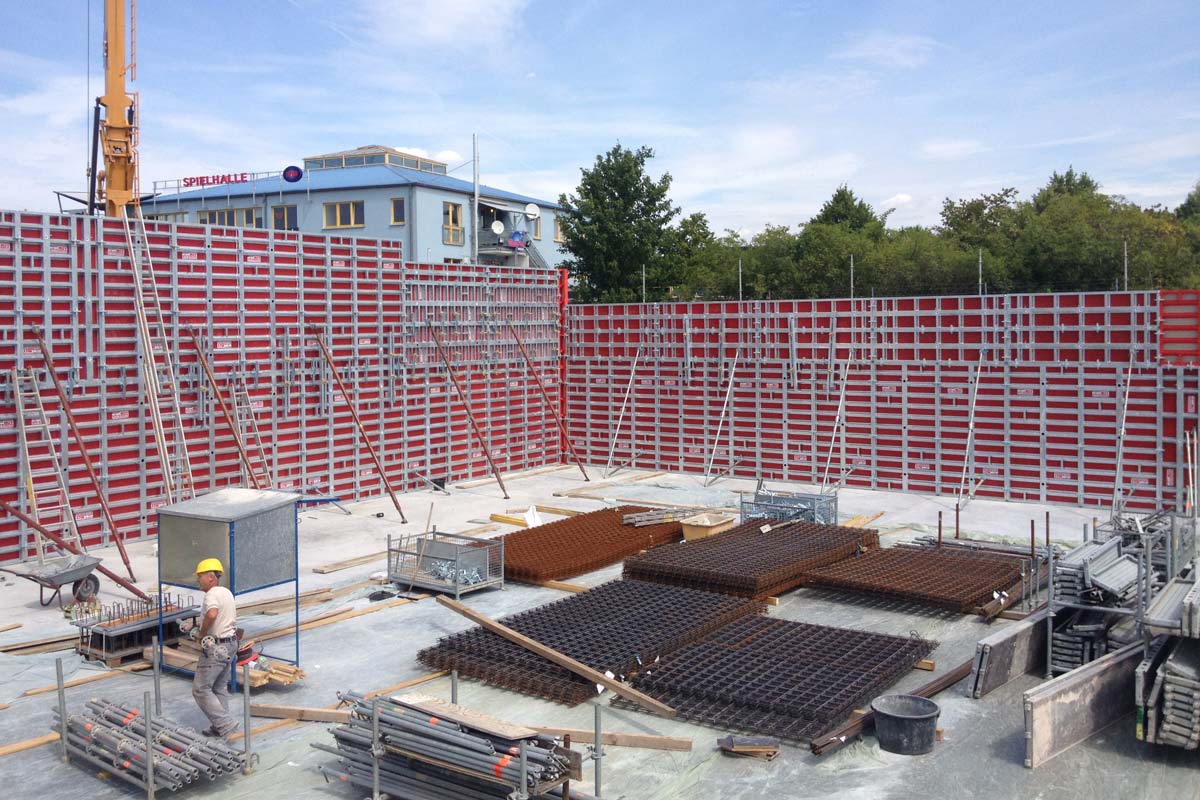

It took about six months to build the structural shell to the unpretentious concrete structure for the “Bowlingarena Extreme” in Schweinfurt. The specification called for high-quality concrete surfaces, although marks from the wall panel formwork would be tolerated – after all, it is a utility structure. Indeed, a regular pattern of formwork joints is often expressly called for as a design feature.

A job for ultraMAX S

With such a specification, Blank realised that this was a clear case for using the heavy-duty ultraMAX S wall panel formwork from Mayer Schaltechnik based in nearby Bergrheinfeld. For this project, Blank hired 330 m² of ultraMAX S, which – designed for a concrete pressure of 80 kN/m² – even satisfies the strict flatness tolerances of DIN 18202, Table 3, Line 7. That means that the deflection of the very stiff steel frames can be practically neglected. Joints between panels remain sealed even under the full pressure of the wet concrete. Like the other Mayer formwork systems, the ultraMAX panel formats are based on a logical 1 m grid. Therefore, site personnel can plan formwork easily without a pocket calculator and work out requirements quickly and dependably.

Walls 3.5 to 6.15 m high had to be built for the bowling centre, which was easily achieved with extended standard elements. The lighter ultraMAX L aluminium wall panel formwork was used for make-up sections < 1 m. That system matches the grid exactly and uses identical connectors and accessories. All ultraMAX panels are connected with the Mayer alignment coupler, and when extending the height, the MST RS 60 alignment coupler ensures that joints are perfectly flush. Site supervisor Ottmar Neumaier confirms this: “Even large areas of formwork were no problem at all, which is an important prerequisite for good formwork setup times.”

The low number of ties needed for ultraMAX S also helped to speed up work on site. Only two ties – both fitted within the panels – are needed for storey heights up to 2.5 m. Therefore, the new system achieves max. 0.4 ties/m². One particular advantage of ultraMAX S was not required on this project – the one-sided ties option, which is particularly interesting for narrow excavations or shafts, or for very high walls, where ties on both sides call for additional scaffolding.

We look forward to hearing from you!

Richtbergstraße 8

97493 Bergrheinfeld

Germany

info@mayerschaltechnik.de

Phone: +49 (0)9721-78960

Fax: +49 (0)9721-789666

Wir freuen uns über Ihre Kontaktaufnahme!

We looking forward to hearing from you!

We look forward to hearing from you!

We look forward to hearing from you!