The leading system for supporting precast concrete floor planks

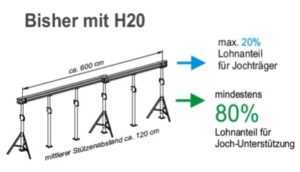

When supporting precast concrete floor planks using conventional methods (H20 timber joists), it is left to the contractor on site to decide on the spacing of the props. This means that, on the one hand, the work cannot be planned properly because no definite quantities can be specified in advance. On the other hand, in some cases it means setting up at least twice as many props as required by the structural calculations.

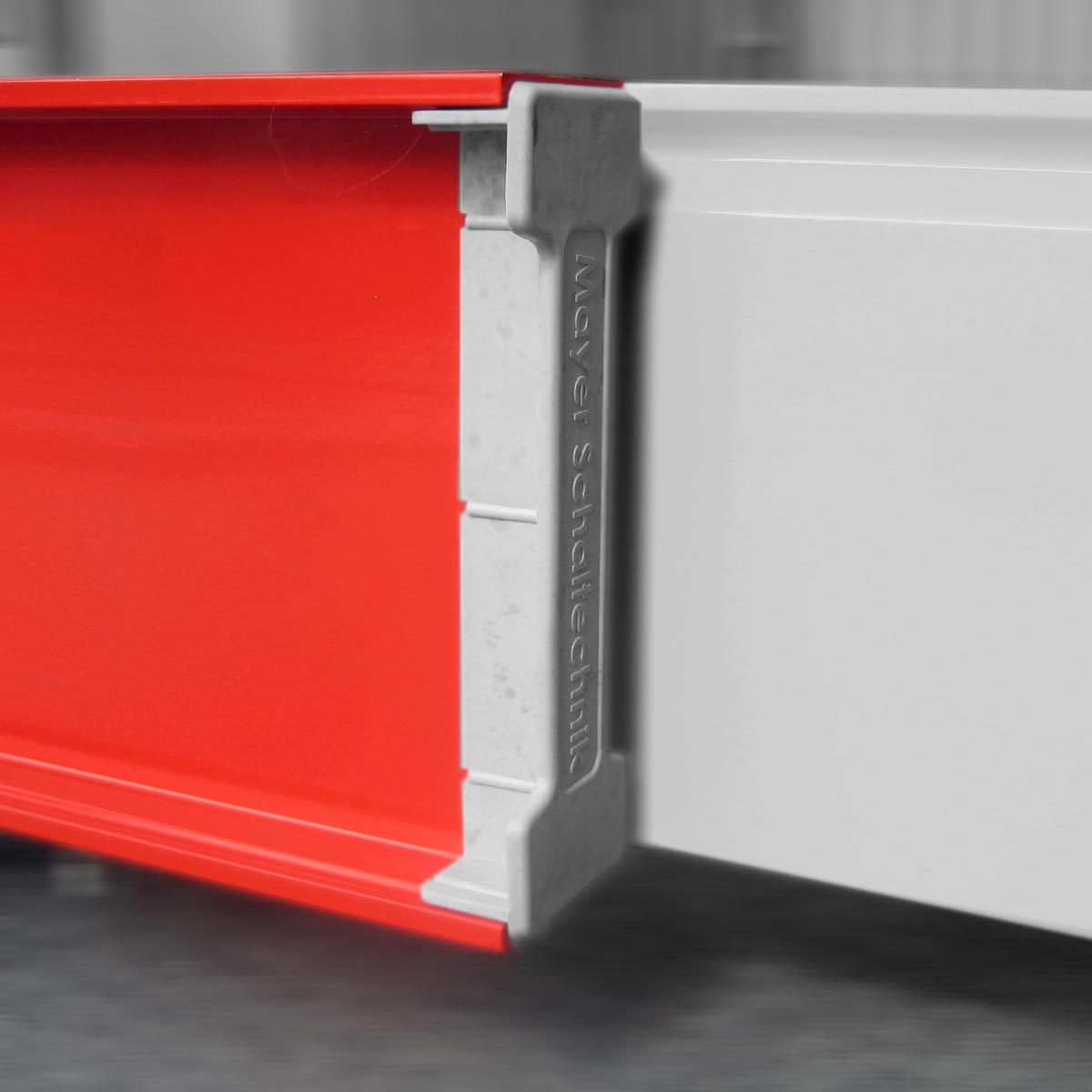

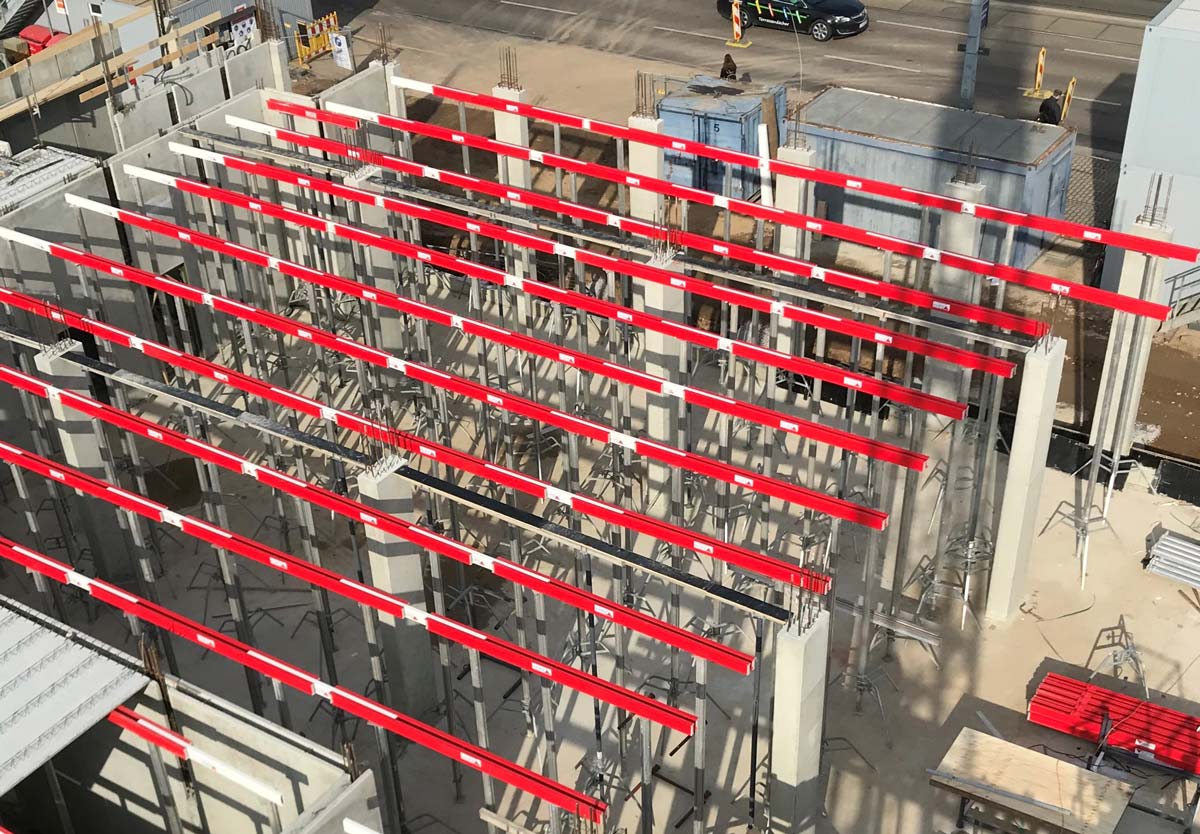

This unsatisfactory practical situation led to Mayer Schaltechnik GmbH formulating a new brief for the supporting beams. There were two main objectives: The number of props used had to be minimised by exploiting the permissible load to the full. And for users, the system had to stipulate unambiguously where a prop was needed. The result of the development work was the miniMAX beam system. In this system, up to 50%(!) fewer individual parts and props are required for a complete beam because a predetermined grid is used for the telescopic props and the loadbearing capacity of the individual props is used to the full.

Comparison of floor slab support systems

Conventional solution with H20 timber joists |

Solution with miniMAX aluminium beams |

|---|---|

| 1 pc. H20 L=360 cm 1 pc. H20 L=250 cm 3 pcs. fork heads 6 pcs. telescopic props 3 pcs. Tripods= 14 separate parts! |

1 pc. double beam L=375 cm 1 pc. single beam L=300 cm 3 pcs. telescopic props 2 pcs. Tripods= 7 separate parts! |

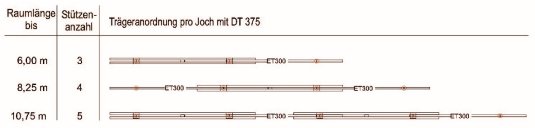

Practical example of beam length and number of props

Example of the use of double beams 375 and single beams 300

Key product advantages

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWe look forward to hearing from you!

Richtbergstraße 8

97493 Bergrheinfeld

Germany

info@mayerschaltechnik.de

Phone: +49 (0)9721-78960

Fax: +49 (0)9721-789666

Wir freuen uns über Ihre Kontaktaufnahme!

We looking forward to hearing from you!

We look forward to hearing from you!

We look forward to hearing from you!